PCB Voids

PCB voids occur anytime there is an un-plated area in the circuit board - either within the hole wall of the PCB drilled plated hole, within hole barrels, or within a solder joint. These voids can disrupt the electrical connections within the circuit, leading to malfunctions.

There are two main types of PCB voids: plating voids and solder voids. Plating voids happen during the electroless copper process when the copper plating does not completely cover the inner walls of the through-hole. Solder voids happen when not enough solder paste is used or when air pockets occur when the solder paste is heated as the air does not escape. In both cases, these voids can render a circuit board inoperable and leave manufacturers with no other option but to scrap it.

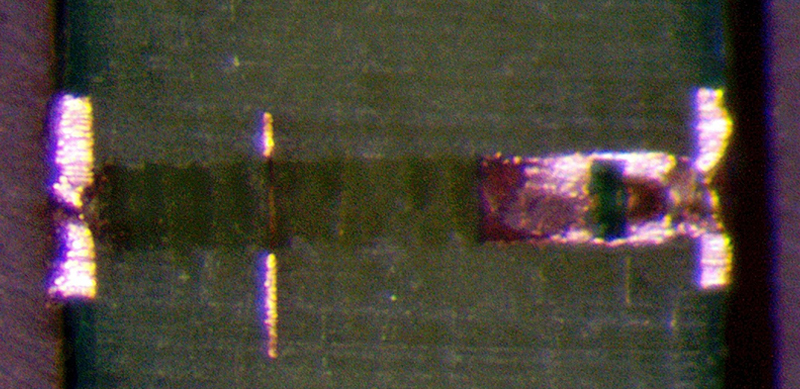

Example of copper plated void during PCB manufacturing.

Plating Voids

Plating voids typically occur due to the drilling process and how it may prepare the through-hole. If a worker uses a dull drill bit, the bit may leave imperfections along the wall instead of a smoother surface. These imperfections may cause the hole wall to be rough and have inner imperfections. When the copper plating is added during the electroless copper process, the copper simply cannot get into every rough spot or crevice in the hole, leaving a non-plated spot.

Another way that plating voids occur is when debris becomes lodged inside the hole. This debris may come from when the worker removes the drill bit, yet the hole is not cleaned out well enough. When the copper enters the hole, it may cover over the debris and other contaminants. However, the debris may later become dislodged from inside the hole, leaving a bare spot that was not plated. The debris inside the hole may cause the copper to create a void as the copper cannot adhere properly to the surface walls of the hole.

Additionally, entrapped air bubbles in the electroless process can prevent copper solution from contacting the barrel wall, thus causing a void.

Solder Voids

A solder void is generated when there are empty spaces within a solder joint. There are a number of factors that can lead to this issue, including a low preheat temperature that prevents the solvent in the flux from vaporizing completely, high levels of flux, solder paste oxidization or using low-quality solder paste, and the design of the PCB itself since some circuit board designs are more prone to voiding than others.

The good news is that solder voids are typically easier to prevent than plating voids. Extending your preheat time, avoiding low-quality and outdated solder paste, and modifying your circuit board stencil are all effective ways to mitigate the risk of solder voids.

PCB Problems

Solder voids and plating voids alike can create a number of issues during the PCB manufacturing process, the biggest issue being a loss of conductivity.

In a PCB, the plating within the holes is used to connect each conductive layer of the circuit board between the layers and from the top to the bottom of the board. The PCB becomes powered by these electrical connections. When there is a void or un-plated area, though, the electrical connection can become disrupted, causing the current to not flow properly. These issues may lead to the PCB malfunctioning or signals not reaching designated areas of the circuit board's components.

When dealing with voids or plating voids, the PCB may have to become scrapped due to failing inspection. For some applications, having just a few voids may allow it to pass the testing. In other cases, though, even a single void can render a circuit board inoperable. For this reason, preventing voids is a key objective in the PCB manufacturing process.

Avoiding Void Issues

The best way to prevent void issues will be based on the types of voids that have commonly occurred during PCB manufacturing processes. To avoid plating issues, manufacturers need to take proactive steps to address how drilling and hole cleaning is conducted.

Drilling too fast, for example, can cause the drill bit to shatter the circuit board's material on the way down, leading to rough and uneven surfaces difficult to coat evenly during deposition and plating. Likewise, using a drill bit that is dull and worn can once again yield uneven surfaces that make plating voids difficult to avoid.

To prevent voids created by the drilling process, drill bits should be sharpened or discarded based on hit count records, drill speeds, and drill feeds. Following cleaning procedures for every drilled hole, proper racking, and controlling as well as monitoring bath plating agitation with the tanks may also help to reduce and eliminate plating voids.

Entrapped air during the electroless process can be avoided with line vibration and angles plating racks.

Manufacturing printed circuit boards can become a costly process when dealing with PCB scrapping due to plating voids. Thankfully, a little precaution and extra attention to detail can prevent most PCB voids.

Capabilities

Payment Methods

Specials Price

Carriers

Support Hobbyist

Certificate

Customer Support

Follow Us

Tel: 1-905-339-2881

Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025

Tel: 1-905-339-2881 Email: sales@goldphoenixpcb.com , tech@goldphoenixpcb.com

Quality Control System

|

Products/Service

|

Friendly Links

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2025